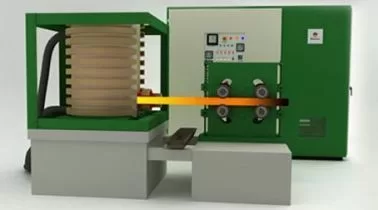

Description

silent features

- Crucible and die heated by two generators and two inductors, with independent regulation of power and temperature

- Maximum safety with the horizontal withdrawal of the material

- High working speed with the special cooling system of the die

- Homogeneity of the metal structure with the secondary cooling system by direct water contact on the profile.

- High-quality standard with a powerful pulling system

- Certainty of maintaining the plant in good condition with the self-diagnosing system and possible alarms with buzzer

- Possibility of placing in complete safety the pre-melting unit for a controlled casting into the holding crucible.

- Protection of the melting chamber by aluminum casing easily and quickly removable to change the consumables.

- Crucible, die, and thermocouples quick change for short setup time.

- Pulling system with four rollers, stepper motor, closing and opening of the rollers with pneumatic control.

- Silent working plant.

- Control of the working parameters by PLC and touch screen video, self-diagnosing, and possible alarms with buzzer.

Reviews

There are no reviews yet.